The General Project

Working closely together with consultants and system integrators allows us to be involved with the project from the design stage, manufacture and factory acceptance test (FAT’s) of the systems. In this specific case, we were contacted by ABB Singapore who was in charge of supplying the electrical protection system for the bark handling process at Oki Pulp & Paper Mills in Indonesia (one of the largest in the world).

Helios Power Solutions had the opportunity to custom build five redundant battery chargers together with battery banks through ABB Singapore, those chargers are responsible for backing-up and securing the continuity of the switching and SCADA system of the bark handing process. We are proud to say that we have been co-operating with our customers in more than 1000 customized CAB’s (cabinets) systems, many of these have been sold to ABB including customised chargers with remote monitoring capabilities designed for ABB ring main units manufactured in New Zealand and exported worldwide.

Key Facts

- End customer: OKI Pulp and Paper Mills

- Location: South Sumatra, Indonesia

- Solution: CAB624 12U 750W 108VDC Redundant Battery Charger + Distribution Panel & Digital Meter

Features

- 12U 19″ Wall Mount Cabinet

- 2 x 750W 108VDC Chargers

- Redundant AC mains inputs

- Passive load sharing for decoupling diodes

- DC output alarm monitoring.

The Solution

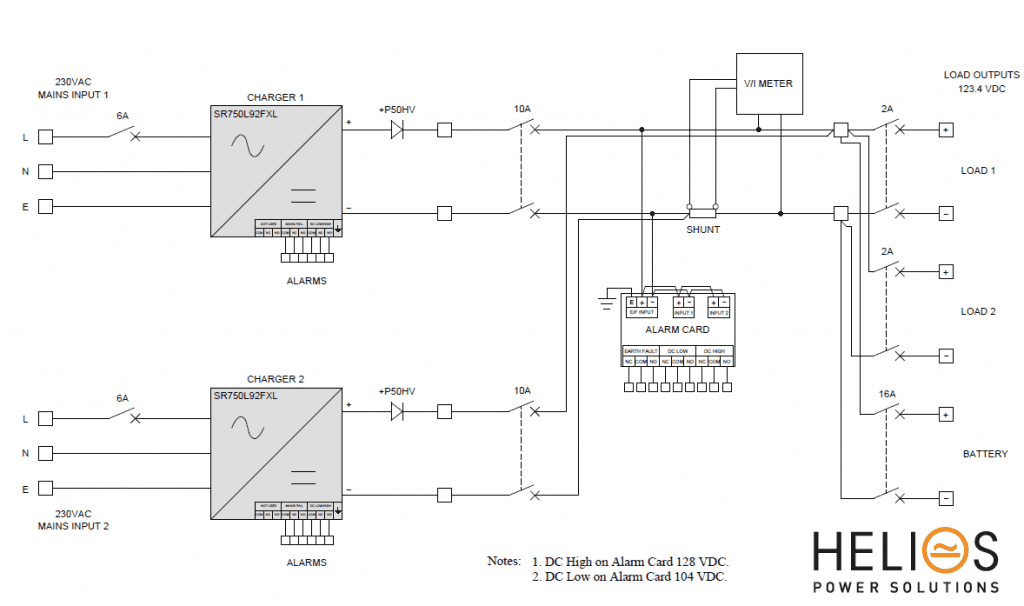

CAB624 is a 750W 108VDC redundant charger in a 12U 19” wall mount cabinet. The system comprises of two SR750L92FXL 750W 108VDC chargers, two P50HV diodes, an alarm card and a digital VI meter along with distribution and protection MCBs. The output voltage of CAB624 is set at 123.4VDC to charge the batteries at 25°C. As it is configured for redundancy it has two separate AC mains input connections each of which is protected by a 6A mains input breaker.

The P50HV decoupling diodes in the positive output of each 2U charger sub-rack ensure passive load sharing and redundancy protection. The system’s output is monitored with an alarm card and a digital meter displaying both the output voltage and current.

Mains Fail and DC Low/High alarms are provided in the form of voltage free contacts for each charger. To prevent false alarms due to fluctuating input and brown outs the Mains Fail alarm will activate after a delay of 30 seconds. The DC Low/High alarm relay will activate when the DC High alarm indicates the charger’s output voltage is ≥128VDC and the DC Low alarm is ≤99VDC. An alarm card provides a System Earth Fault, System DC High and a System DC Low alarm in the form of voltage free contacts. A System DC Low alarm will activate if the system output voltage ≤104VDC and a System DC High alarm will activate if the system output voltage ≥128VDC.

The system includes a DC distribution of two load outputs labeled as Load 1 and Load 2, each protected by a 2A circuit breaker. A 16A 2P battery breaker is supplied to protect the battery.All connections points are located on the terminal panel in the back of the cabinet and can be accessed by swinging the cabinet away from the mounted back panel. Six 10mm DIN terminals are provided for the dual AC inputs, 21 2.5mm DIN terminals are provided for the alarms and six 10mm DIN terminals are provided for the battery and two load outputs.

About OKI Pulp & Paper Mills

Asia Pulp & Paper (APP) is operating a paper and pulp mill in Ogan Komering Ilir (OKI) South Sumatra, Indonesia. The OKI mill is co-owned by APP subsidiaries Pindo Deli Pulp and Tjimi Kimia, each holding 47.58% of the shares, with the remaining shares being controlled by Muba Green Indonesia. The mill has a capacity of 2.8 millions tonnes per year. The project required a total investment of USD2.6 billion, of which USD1.8 billion is funded by the China Development Bank and the remaining USD800 million is funded by the shareholders. According to the Environmental Impact Assessment the new mill is to be supplied by the surrounding plantations, mainly PT. Bumi Mekar Hijau, Sebangun Bumi Andalas and PT. Bumi Andalas Permai.