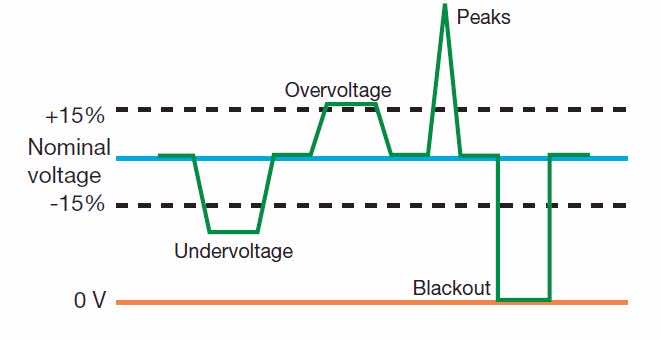

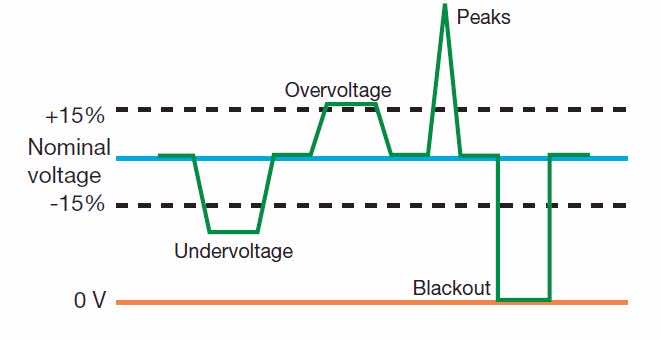

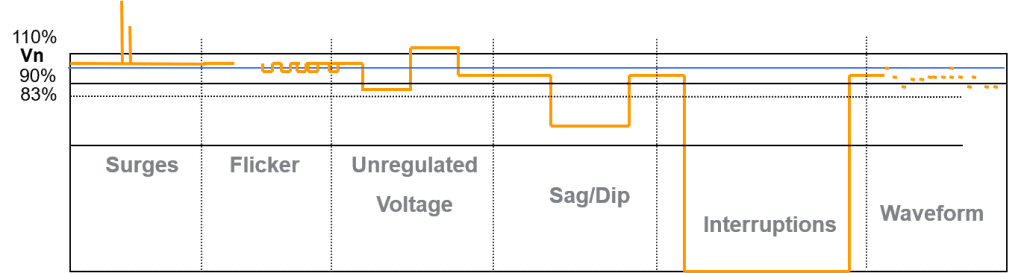

Power quality (PQ) related issues are of most concern nowadays. The widespread use of electronic equipment, such as information technology equipment, power electronics such as adjustable speed drives (VSD), programmable logic controllers (PLC), energy-efficient lighting, led to a complete change of electric loads nature. These loads are simultaneously the major causers and the major victims of power quality problems. Due to their non-linearity, all these loads cause disturbances in the voltage waveform.¹Electrical equipment is occasionally exposed to transient overvoltages (surges/spikes), swells, flickers, unregulated voltages, voltage dips/sags, interruptions or waveform disturbances (power factor, harmonics, others).

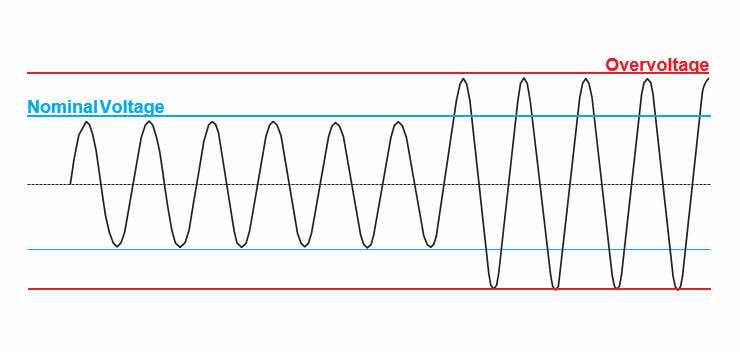

An overvoltage is an increase in voltage for a time of over 10 ms. Overvoltages can be induced by the disconnection of heavy loads (interruption 2. of production processes in industries: the reduction in the speed of electric motors, arc furnaces, rolling mills etc.) or by natural events such as lightning.Causes: Lightning, switching of lines or power factor correction capacitors, disconnection of heavy loads.Consequences: Destruction of components (particularly electronic components) and of insulation materials, data processing errors or data loss, electromagnetic interference.

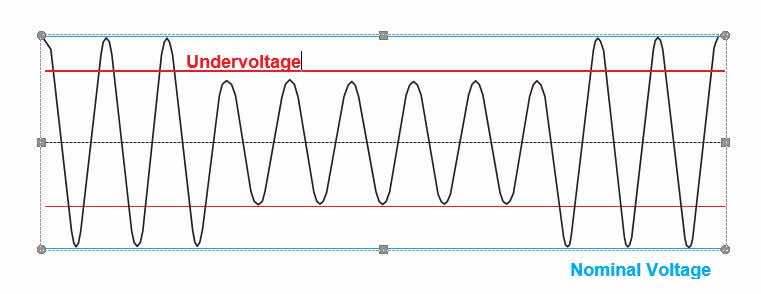

An overvoltage is an increase in voltage for a time of over 10 ms. Overvoltages can be induced by the disconnection of heavy loads (interruption 2. of production processes in industries: the reduction in the speed of electric motors, arc furnaces, rolling mills etc.) or by natural events such as lightning.Causes: Lightning, switching of lines or power factor correction capacitors, disconnection of heavy loads.Consequences: Destruction of components (particularly electronic components) and of insulation materials, data processing errors or data loss, electromagnetic interference. A voltage sag is a short duration (i.e , 0.5 – 60 cycles) decrease in the RMS voltage magnitude, usually caused by a fault somewhere on the power system. Voltage sags are the most important power quality problem facing many industrial customers especially those with a process. A sag is when the voltage drops below 90% of nominal.Causes: Faults on the transmission or distribution network (most of the times on parallel feeders). Faults in consumer’s installation. Connection of heavy loads and start-up of large motors.Consequences: Malfunction of equipment used in modern industrial plants ( process controllers , PLC , Variable Speed Drives) is actually becoming more sensitive to voltage sags as the complexity of the equipment increases.

A voltage sag is a short duration (i.e , 0.5 – 60 cycles) decrease in the RMS voltage magnitude, usually caused by a fault somewhere on the power system. Voltage sags are the most important power quality problem facing many industrial customers especially those with a process. A sag is when the voltage drops below 90% of nominal.Causes: Faults on the transmission or distribution network (most of the times on parallel feeders). Faults in consumer’s installation. Connection of heavy loads and start-up of large motors.Consequences: Malfunction of equipment used in modern industrial plants ( process controllers , PLC , Variable Speed Drives) is actually becoming more sensitive to voltage sags as the complexity of the equipment increases. Interruptions occur when a source-side protective device opens a section of the circuit due to a fault condition. The interruption may be sustained or momentary. Sustained interruptions last minutes or hours while momentaries last few seconds.Causes of short interruptions: Mainly due to the opening and automatic reclosure of protection devices to decommission a faulty section of the network. The main fault causes are insulation failure, lightning and insulator flashover.Consequences: Tripping of protection devices, loss of information and malfunction of data processing equipment.Stoppage of sensitive equipment, such as ASDs, PCs, PLCs, if they’re not prepared to deal with this situation.Causes of long interruptions: Eqquipment failure in the power system network, storms, animals and objects ( trees, cars) striking lines or poles, fire, human error, bad coordination or failure of protection devices.Consequences: Systems shut down.

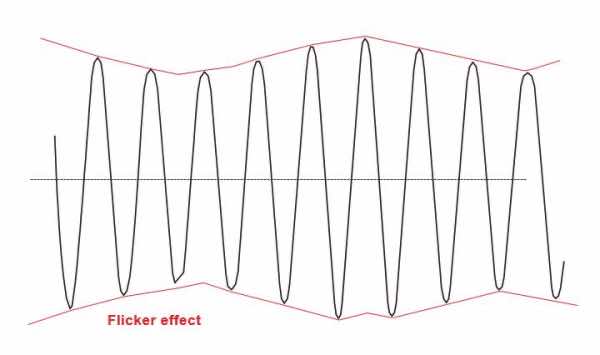

Interruptions occur when a source-side protective device opens a section of the circuit due to a fault condition. The interruption may be sustained or momentary. Sustained interruptions last minutes or hours while momentaries last few seconds.Causes of short interruptions: Mainly due to the opening and automatic reclosure of protection devices to decommission a faulty section of the network. The main fault causes are insulation failure, lightning and insulator flashover.Consequences: Tripping of protection devices, loss of information and malfunction of data processing equipment.Stoppage of sensitive equipment, such as ASDs, PCs, PLCs, if they’re not prepared to deal with this situation.Causes of long interruptions: Eqquipment failure in the power system network, storms, animals and objects ( trees, cars) striking lines or poles, fire, human error, bad coordination or failure of protection devices.Consequences: Systems shut down. The flicker effect is a flickering of lights induced by rapid variations in voltage.These voltage variations are caused by loads in which the power absorption varies very quickly: arc furnaces, welding machines, rolling machines, laser cutters.Consequences: Flicker impacts workplace safety and productivity, the comfort of living spaces, and, according to recent research, our overall health and emotional wellbeing. From a safety perspective, for example, fast-rotating elements present in an operator’s field of vision appear to be moving less quickly or stopped with excessive flicker. From a photobiological perspective, prolonged exposure to excessive flicker causes neurological problems such as headaches, migraine, and even epilepsy.From a technology perspective, flicker strongly impacts lighting for digital image capture, particularly in TV studios and stadiums. Strict broadcast requirements demand use of proper power systems to avoid camera image artifacts, particularly stroboscopic effects during high-speed capture for slow-motion replay. ²

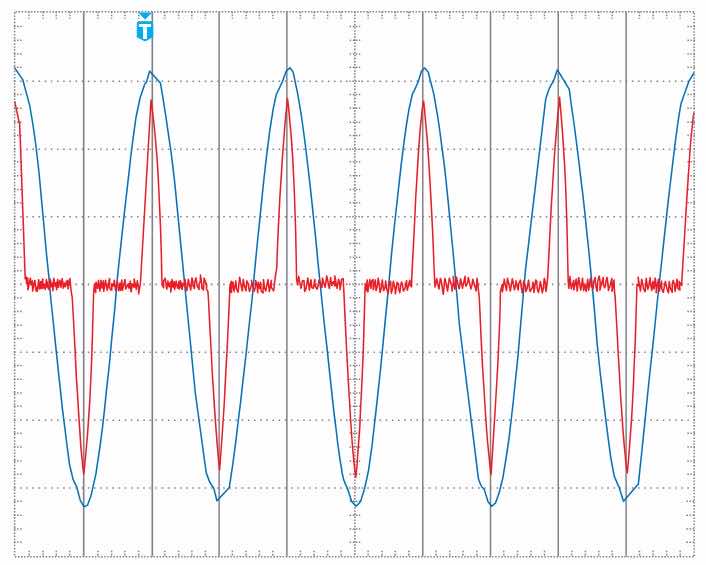

The flicker effect is a flickering of lights induced by rapid variations in voltage.These voltage variations are caused by loads in which the power absorption varies very quickly: arc furnaces, welding machines, rolling machines, laser cutters.Consequences: Flicker impacts workplace safety and productivity, the comfort of living spaces, and, according to recent research, our overall health and emotional wellbeing. From a safety perspective, for example, fast-rotating elements present in an operator’s field of vision appear to be moving less quickly or stopped with excessive flicker. From a photobiological perspective, prolonged exposure to excessive flicker causes neurological problems such as headaches, migraine, and even epilepsy.From a technology perspective, flicker strongly impacts lighting for digital image capture, particularly in TV studios and stadiums. Strict broadcast requirements demand use of proper power systems to avoid camera image artifacts, particularly stroboscopic effects during high-speed capture for slow-motion replay. ² Devices that generate harmonics are present in the industrial sector, the service sector and also in the home. Harmonics are generated by non-linear loads: a load is defined as non-linear when the current which it absorbs does not have the same form as the voltage that supplies it. Power electronics such as rectifiers, inverters, electronic starters, variable frequency motor drives, switching power supplies, discharge lamps are classic examples of non-linear loads. The powering of non-linear loads causes the appearance of THDIs (Total Harmonic Distortion Currents) circulating in the system. In turn, harmonic currents that pass through the power supply circuit (lines and transformers), cause the deformation of the mains voltage: the harmonic distortion in voltage THDU (Total Harmonic Distortion Voltage).Consequences:

Devices that generate harmonics are present in the industrial sector, the service sector and also in the home. Harmonics are generated by non-linear loads: a load is defined as non-linear when the current which it absorbs does not have the same form as the voltage that supplies it. Power electronics such as rectifiers, inverters, electronic starters, variable frequency motor drives, switching power supplies, discharge lamps are classic examples of non-linear loads. The powering of non-linear loads causes the appearance of THDIs (Total Harmonic Distortion Currents) circulating in the system. In turn, harmonic currents that pass through the power supply circuit (lines and transformers), cause the deformation of the mains voltage: the harmonic distortion in voltage THDU (Total Harmonic Distortion Voltage).Consequences:

Main Disturbances

1. Overvoltage or Spikes:

An overvoltage is an increase in voltage for a time of over 10 ms. Overvoltages can be induced by the disconnection of heavy loads (interruption 2. of production processes in industries: the reduction in the speed of electric motors, arc furnaces, rolling mills etc.) or by natural events such as lightning.Causes: Lightning, switching of lines or power factor correction capacitors, disconnection of heavy loads.Consequences: Destruction of components (particularly electronic components) and of insulation materials, data processing errors or data loss, electromagnetic interference.

An overvoltage is an increase in voltage for a time of over 10 ms. Overvoltages can be induced by the disconnection of heavy loads (interruption 2. of production processes in industries: the reduction in the speed of electric motors, arc furnaces, rolling mills etc.) or by natural events such as lightning.Causes: Lightning, switching of lines or power factor correction capacitors, disconnection of heavy loads.Consequences: Destruction of components (particularly electronic components) and of insulation materials, data processing errors or data loss, electromagnetic interference.2. Swells

Momentary increase of the voltage, at the power frequency, outside the normal tolerances, with duration of more than one cycle and typically less than a few seconds. Causes: Start/stop of heavy loads, badly dimensioned power sources, badly regulated transformers (mainly during off-peak hours).Consequences: Data loss, flickering of lighting and screens, stoppage or damage of sensitive equipment, if the voltage values are too high.3. Voltage Sags

A voltage sag is a short duration (i.e , 0.5 – 60 cycles) decrease in the RMS voltage magnitude, usually caused by a fault somewhere on the power system. Voltage sags are the most important power quality problem facing many industrial customers especially those with a process. A sag is when the voltage drops below 90% of nominal.Causes: Faults on the transmission or distribution network (most of the times on parallel feeders). Faults in consumer’s installation. Connection of heavy loads and start-up of large motors.Consequences: Malfunction of equipment used in modern industrial plants ( process controllers , PLC , Variable Speed Drives) is actually becoming more sensitive to voltage sags as the complexity of the equipment increases.

A voltage sag is a short duration (i.e , 0.5 – 60 cycles) decrease in the RMS voltage magnitude, usually caused by a fault somewhere on the power system. Voltage sags are the most important power quality problem facing many industrial customers especially those with a process. A sag is when the voltage drops below 90% of nominal.Causes: Faults on the transmission or distribution network (most of the times on parallel feeders). Faults in consumer’s installation. Connection of heavy loads and start-up of large motors.Consequences: Malfunction of equipment used in modern industrial plants ( process controllers , PLC , Variable Speed Drives) is actually becoming more sensitive to voltage sags as the complexity of the equipment increases.4. Short and Long Interruptions:

Interruptions occur when a source-side protective device opens a section of the circuit due to a fault condition. The interruption may be sustained or momentary. Sustained interruptions last minutes or hours while momentaries last few seconds.Causes of short interruptions: Mainly due to the opening and automatic reclosure of protection devices to decommission a faulty section of the network. The main fault causes are insulation failure, lightning and insulator flashover.Consequences: Tripping of protection devices, loss of information and malfunction of data processing equipment.Stoppage of sensitive equipment, such as ASDs, PCs, PLCs, if they’re not prepared to deal with this situation.Causes of long interruptions: Eqquipment failure in the power system network, storms, animals and objects ( trees, cars) striking lines or poles, fire, human error, bad coordination or failure of protection devices.Consequences: Systems shut down.

Interruptions occur when a source-side protective device opens a section of the circuit due to a fault condition. The interruption may be sustained or momentary. Sustained interruptions last minutes or hours while momentaries last few seconds.Causes of short interruptions: Mainly due to the opening and automatic reclosure of protection devices to decommission a faulty section of the network. The main fault causes are insulation failure, lightning and insulator flashover.Consequences: Tripping of protection devices, loss of information and malfunction of data processing equipment.Stoppage of sensitive equipment, such as ASDs, PCs, PLCs, if they’re not prepared to deal with this situation.Causes of long interruptions: Eqquipment failure in the power system network, storms, animals and objects ( trees, cars) striking lines or poles, fire, human error, bad coordination or failure of protection devices.Consequences: Systems shut down.5. Flicker Effect

The flicker effect is a flickering of lights induced by rapid variations in voltage.These voltage variations are caused by loads in which the power absorption varies very quickly: arc furnaces, welding machines, rolling machines, laser cutters.Consequences: Flicker impacts workplace safety and productivity, the comfort of living spaces, and, according to recent research, our overall health and emotional wellbeing. From a safety perspective, for example, fast-rotating elements present in an operator’s field of vision appear to be moving less quickly or stopped with excessive flicker. From a photobiological perspective, prolonged exposure to excessive flicker causes neurological problems such as headaches, migraine, and even epilepsy.From a technology perspective, flicker strongly impacts lighting for digital image capture, particularly in TV studios and stadiums. Strict broadcast requirements demand use of proper power systems to avoid camera image artifacts, particularly stroboscopic effects during high-speed capture for slow-motion replay. ²

The flicker effect is a flickering of lights induced by rapid variations in voltage.These voltage variations are caused by loads in which the power absorption varies very quickly: arc furnaces, welding machines, rolling machines, laser cutters.Consequences: Flicker impacts workplace safety and productivity, the comfort of living spaces, and, according to recent research, our overall health and emotional wellbeing. From a safety perspective, for example, fast-rotating elements present in an operator’s field of vision appear to be moving less quickly or stopped with excessive flicker. From a photobiological perspective, prolonged exposure to excessive flicker causes neurological problems such as headaches, migraine, and even epilepsy.From a technology perspective, flicker strongly impacts lighting for digital image capture, particularly in TV studios and stadiums. Strict broadcast requirements demand use of proper power systems to avoid camera image artifacts, particularly stroboscopic effects during high-speed capture for slow-motion replay. ²6. Harmonic Distortion

Origen of Harmonics:

Devices that generate harmonics are present in the industrial sector, the service sector and also in the home. Harmonics are generated by non-linear loads: a load is defined as non-linear when the current which it absorbs does not have the same form as the voltage that supplies it. Power electronics such as rectifiers, inverters, electronic starters, variable frequency motor drives, switching power supplies, discharge lamps are classic examples of non-linear loads. The powering of non-linear loads causes the appearance of THDIs (Total Harmonic Distortion Currents) circulating in the system. In turn, harmonic currents that pass through the power supply circuit (lines and transformers), cause the deformation of the mains voltage: the harmonic distortion in voltage THDU (Total Harmonic Distortion Voltage).Consequences:

Devices that generate harmonics are present in the industrial sector, the service sector and also in the home. Harmonics are generated by non-linear loads: a load is defined as non-linear when the current which it absorbs does not have the same form as the voltage that supplies it. Power electronics such as rectifiers, inverters, electronic starters, variable frequency motor drives, switching power supplies, discharge lamps are classic examples of non-linear loads. The powering of non-linear loads causes the appearance of THDIs (Total Harmonic Distortion Currents) circulating in the system. In turn, harmonic currents that pass through the power supply circuit (lines and transformers), cause the deformation of the mains voltage: the harmonic distortion in voltage THDU (Total Harmonic Distortion Voltage).Consequences:- The electronic power regulation systems may be disturbed by the fact of having to work with voltages that are not perfectly sinusoidal.

- The electronic signal systems, designed to work with very low currents, can easily be “fooled”by the presence of disturbances induced by high-frequency electromagnetic fields.

- Increased probability in occurrence of resonance.

- Neutral Overload in 3-phase systems.

- Overheating of all cables and equipment and loss of efficiency in electric machines.

7. Low Power Factor ( It’s not a power quality problem but it affects the efficiency of your electrical system)

A poor power factor (0.95 PF or less) is caused when a circuit has a high level of inductive loads (electric motors, lighting ballasts, transformers) causing the circuit voltage and current waveforms to be out of phase and the resultant using more apparent power than is needed.Benefits of using Power Factor correction:- Improved efficiency and reduction in power demand therefore saving on electricity costs.

- Reduced CO2 emissions.

- Increased system capacity

- Hospitals & Granaries

- Saw Mills

- Plastic ( especcially extruders)

- Breweries

- Chemicals