Railway electrification systems rely on a steady DC supply to both power their DC motors and the control/energy circuits. These DC-traction systems are more energy efficient than their coal, gas, or diesel-based counterparts while also reducing CO2 emissions. DC-to-DC converters play a crucial role in improving the energy efficiency and power quality of electrified railways. Electronic components used in these applications will be subjected to extremes in temperature, humidity, vibration, and mechanical shock. As such, they require a high degree of electrical and structural integrity to be able to withstand these conditions and reliably operate.

Using DC-DC Converters for Railway Applications

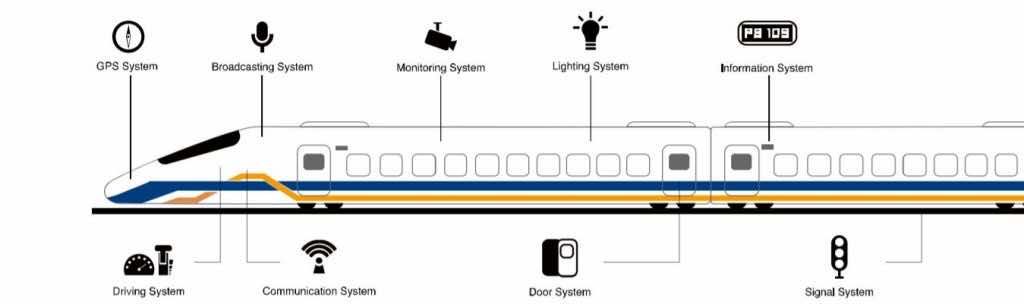

Regenerative braking relies on the use of a large bidirectional DC-to-DC converter to send power back to the battery bank or energy storage system (ESS) from the DC feeder line. Smaller DC conversion is necessary in modern railways to distribute a continuous supply of power to all electronic devices and subsystems within the coach. These auxiliary systems include higher voltage critical systems such as engine controls, motor drive controls, and braking systems, as well as lower voltage secondary systems including lighting, battery charging, indication lamp, pump, and information displays, and electric door openers.

The conventional solution often involves the use of an input filter, a 3-phase inverter, and a low frequency transformer in order to provide electrical isolation between the overhead line voltage and the auxiliary power supply equipment. Typically, this transformer is large and bulky, adding extra mass to an already space- and weight-constrained application. Instead, isolated DC-to-DC converters can be used to meet the size, weight, and power requirements of modern railway applications. The goal is to convert the high 750V, 1500V, and/or 3000V input voltage to a regulated 24, 28, 36, 48, 72, 96, or 110 volt output.The power distribution within the train from the main supply also requires a chain of DC-to-DC conversion to the secondary systems. As stated earlier, the nominal input voltages can vary from as low as 24 volts to as high as 110 volts; from there, a regulated 3.3, 5, 12, 15,or 24 volt output is necessary. The EN 50155 European standard for railway electrical equipment requires that the nominal input voltage can fluctuate between 0.7 and 1.25 times the rated voltage. The standard also allows short-term deviations between 0.6 and 1.4 times the nominal input voltage.In other words, a 110V system would require a continuous voltage range between 67.2 volts and 120 volts as was a fluctuation voltage range from 66 volts to 154 volts. DC-to-DC converters can support wide input ranges to cover more than one nominal input voltage. For example, a converter for the common 72V and 110V railway input voltages would need an operating input voltage range from 43.2 volts to 154 volts (see Table 1).

36-160Vdc Wide Input DC-DC Converters with 3000VAC reinforced Isolation

Helios offers the RHKW, RHMW, and RHDW series of mountable DC-to-DC converters rated for railway and industrial applications. These devices all offer 3,000 VAC of reinforced isolation as well as a wide input range from 36 volts up to 160 volts, allowing them to be used in 72V, 96V and 110V railway applications.DC-DC Converters EN 50155 Approved – Related Products

For technical support about our off the shelf products and customised power conversion solutions, get in touch today.