Description

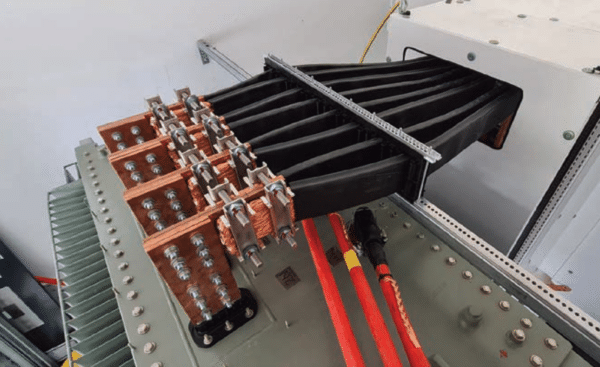

nVent Eriflex Flexibar – Flexible Busbar

After extensive research, nVent ERIFLEX is proud to establish a new gold standard in terms of insulation for flexible busbar called nVent ERIFLEX Flexibar Advanced. The new product is low smoke, halogen-free and flame retardant all while maintaining the level of flexibility and reliability that our partners have come to expect from nVent ERIFLEX Flexibar. Compared to standard PVC insulation, nVent ERIFLEX Flexibar Advanced does not generate corrosive gases and produces a relatively low smoke opacity in accordance with ISO 5659-2.

What is nVent ERIFLEX Flexibar?

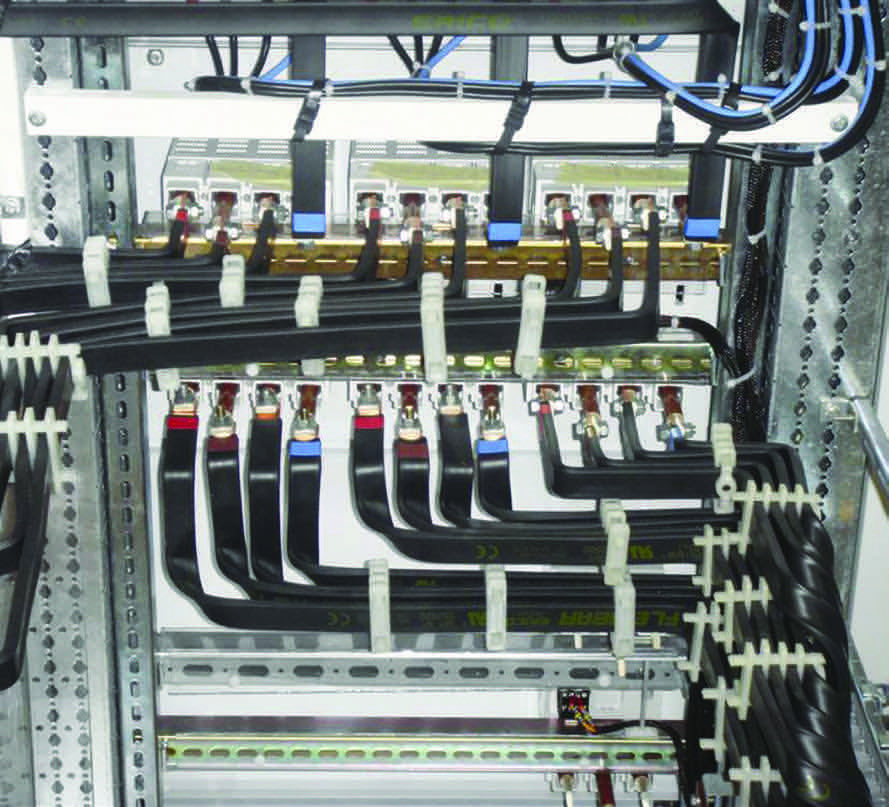

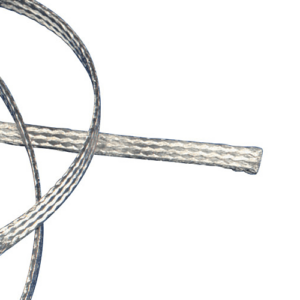

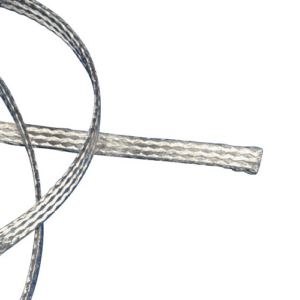

Flexibar can be used for making power connections on devices or for creating links that can be adapted to any requirement. Guaranteeing safety and high quality finish, they provide an undeniably attractive touch.Based on the most commonly used sizes and the electrical capacities of the usual nominal values, the Flexibar range of flexible bars is suitable for most connection or linking requirements. Flexibar consists of pure electrolytic copper (tinned or plain) layers within a protective self-extinguishing sleeve.

- Flexibar Advanced: TPE Compound (haloge-free, Flame retardant, Low Smoke and 115°C)

The individual layers slide smoothly against one another allowing the Flexibar to be easily shaped to fit a wide range of panel layouts. The insulating sleeve is grooved on the inner surface, reducing the contact surface with the laminates to less than 20%, increasing flexibility and making installation easier. It also helps releasing constraint on insulation, improving safety and reliability.

Easily formed even in its largest size, Flexibar vastly improves design and assembly flexibility and the aesthetic of finished panels. All Flexibar cross-sections can be bended, folded, or twisted with a very small bending radius for shorter and more compact power connections between main power and distribution equipment, between transformers and busduct, between busduct and electrical cabinets, and many other types of connections.

When compared to standard round cable, Flexibar offers space saving advantages due to a tighter bend radius and the ability to replace multiple round conductors with a single piece of Flexibar.Modification of fewer conductors and the elimination of ring terminals can result in significant cost and labor reduction.

Flexibar is a flexible busbar wire replacement solution for low voltage applications available from 19.5 mm² up to 1200 mm² and 125 A to 2800 A with a single conductor per phase or up to 4500A with 3 conductors per phase.

Typical Uses

- Heavy-duty power interconnection

- Overcome vibration/alignment problems

- Circuit breaker, generator & prefabricated power network conductor

- Expansion joints

- Variable terminating positions

- Machine connections

- Movable connection from massive busbar system

- Alternative to large & multiple cables

- Alternative to rigid busbar

Typical Market

- Switchgear & control equipment

- Transport

- Electrical equipment manufacturers

- Power generation

- Machinery manufacturer