New Dual Output DC Power System for Wireless Communications Networks

48V And 24V DC Power System With Integrated 12V Or 24V DC Converter Managing your backup system and critical loads with two different voltage levels is now possible with the new ICT Hybrid Ultra and ICT Hybrid Power Series. The dual output voltage configuration brings more flexibility while maintaining a high level of reliability with the standard battery management features and ethernet enabled monitoring capabilities. The new series are ideal for restricted space applications where the primary DC voltage is positive or negative 48V or 24V DC, and auxiliary voltage of 12V or 24V DC is required to power certain devices at the site. ICT Hybrid Ultra Series Up to 7500W output Power 700W/1500W AC-DC Power modules – 48V or 24V DC output 700W DC-DC Converter Module – 12 VDC output Dual 100 amp battery breakers with battery management module 4 or 8 fully managed load outputs Digital and analog inputs for temperature and site sensors Full range of certifications including CSA/UL, FCC Class B, CE, ROHS ICT Hybrid Power Series Up to 3000W output Power 700W/1500W AC-DC Power modules – 48V or 24V DC output 700W DC-DC Converter Module – 12 VDC output Dual 100 amp battery breakers with battery management module Digital and analog inputs for temperature and site sensors Full range of certifications including CSA/UL, FCC Class B, CE, ROHS Applications Two-way Communications Networks Trunked Radios Systems Backhaul DAS SCADA Security & Surveillance Main Features of Modules Integrated Intelligent Control Module – ICM Controller TCP/IP remote Ethernet communications for monitoring and control Embedded web server for plug and play set up HTTP/HTTPS, SMTP, SNMPv1/v2c/v3 protocols supported AC input voltage, DC output voltage, system current reporting (local and Ethernet) Four site monitoring sensor inputs with alarm reporting Local and remote output voltage and current limit adjustment Up to 30 days logging at 1 minute sampling rate, csv file download, major event logging Integrated Load Distribution Module (just for Hybrid Ultra Series) Display current reading of each of four load outputs Remote on/off control of individual outputs or entire load bus over Ethernet User definable alarm level indications (sent via Form C and Ethernet) User-definable load disconnect and reconnect levels Definable automatic load shedding Auto-ping automatic power cycling of specified load outputs Power-up delay sequencing Battery Management Module Temperature-compensated charging Display of battery voltage status Battery current, state of charge, run time remaining reporting Adjust LVD settings Configure advanced battery management features such as Boost charge parameters Max charge current Battery capacity Battery test timer Battery discharge test cut-off voltage. This features are available with Lead Acid batteries. The modular series is compatible with Lithium-ion batteries but battery monitoring and reporting is done by the battery itself. (read Using DC Power Supplies and Battery Chargers with Lithium-ion batteries for more info) Contact Us For Technical Assistance For technical support about our off the shelf products and customised power conversion solutions, get in touch today. Contact Our Engineering Team

How to choose the right DC Power & Backup System for your leaky feeder Application?

If you’re looking to install or replace a leaky feeder communication system, choosing the right DC power supply and battery backup is a key decision. Leaky feeders are underground communications systems that make wireless comms possible within mines and other underground challenging environments. They’re often essential for safety and productivity, and it’s crucial they have an uninterrupted power supply (UPS) you can trust. At Helios, we design DC & AC power conversion solutions for critical infrastructure. We’ve supplied DC power backup systems for leaky feeders in mines across Australia and South America, and we can customise the ideal solution for your application. In this article, we’ll look at: What is a leaky feeder, and how does it work What’s important about the DC power supply and battery backup Other Helios solutions for the mining sector What is a leaky feeder A Leaky feeder works by running a linear cable (radiating cable) through mines, tunnels or structures. These cables are then used as an antenna to connect devices for voice, video and high-speed data communications. They’re a reliable, robust communication system that you can scale using amplifiers. These attributes make them ideal for mining, though you also find leaky feeders everywhere, from railway tunnels to commercial aircraft. In a mine, a leaky feeder might look like this ⇒ Central to the leaky feeder is the Head End Base Station. This 19” rack mount cabinet not only connects the underground network and the surface antenna network. It also: Modulates and demodulates the VHF signals Splits and combines multiple channels Performs remote diagnostics Manages correct impedance matching Identifies faults Reports back to the network performance monitor Provides DC power supply to power the leaky feeder network Backs up power supply with a battery charger and battery bank The last two points are potentially the most important. Why? Because no power, no leaky feeder, no comms. You could have an unsafe work environment without a reliable UPS solution for your leaky feeder. Top 5 considerations for a leaky feeder DC power system 1. How robust is the DC power supply and backup? Your DC power system and backup need to operate flawlessly in a dusty, hot environment. Only shortlist solutions that are convection cooled (no fans) or have a high operating temperature. 2. Does it have a versatile design? Look for solutions that are easy to install (i.e. rack mounted), have a wide input range for VAC (to withstand voltage fluctuations), and can have two different voltages levels ( 30V for the amplifiers and other for the charging batteries). 3. Can you monitor the system or control it remotely? Realtime monitoring of the power supply should be a non-negotiable in any modern leaky feeder. So too should be remote monitoring via TCP/IP. 4. What customisations can you make? You should be able to customise your DC power solution to your needs. Whether you want batteries charged at 12V, 24V or 48V, digital or analogue meters, lithium or lead-acid batteries – it should be your call. 5. Is the power system locally produced and supported? If something happens, how reliable is the supply chain for repairs? Are the components produced locally or on-hand? Are technicians available to support your teams? How does the Helios solution stack up? At Helios work closely with leaky feeder producers, mining communication consultants and mining operations in Australia. So we understand what works best in mines here and how to make the customisations you might need. The Helios Power Systems leaky feeder power supply is a battery-backed, convection-cooled (no fans) DC power system that can be fully monitored and is designed for harsh underground mining applications. This system has the DC power supply for charging the backup system (batteries) and the 30VDC required for powering up the leaky feeder network (power amplifiers) in the same 2U rack unit. In case of mains failure the battery bank can provide power for ### hours. Standard Features Convection cooled ideal for dusty environments ( this depends on the output power required) Wide input range 180-300VAC (capable of handling transient spikes) 12V, 24V or 48VDC options for battery backup 30VDC to power amplifiers Short circuit and OVP protection High operation temperature Battery Circuit breakers Easy installation, diagnosis and management Active relays to turn loads ON/OFF Designed and made in Australia Optional Features Digital or analogue meters for Voltage and Current Remote control and reporting over TCP/IP. Ability to report back to the control room in real-time LED Indications alarms – front panel Terminals – Phoenix or Stud N+1 Redundancy Specific alarms System reset button Battery Backup type (lithium and lead-acid) and autonomy Conformal coating Some of the Leaky Feeder DC Power Systems manufactured by Helios Power Solutions AMP-K4405 30VDC, 5.5A Power Supply with 48VDC Battery Charger AMP-K4310 30VDC, 5.5A Power Supply with 24VDC Battery Charger AMP-K6227 Dual output leaky feeder power supply 2x36V constant current limited at 5A + Dual 55V 20A float Lithium batteries charger Other Helios solutions for mining applications Helios also support the mining sector with a range of other custom solutions for operational safety and continuity. These include: Battery chargers and battery banks for substations and switchgears Power supplies and DC distribution panels for SCADA & telemetry networks Fully customised power distribution panels via TCP/IP Power systems for security surveillance and emergency systems For technical support about our off the shelf products and customised power conversion solutions, get in touch today. Contact Our Engineering Team

How to Choose the Right 110VDC to 230VAC Rack Mounted Inverter

Inverters play a vital role within power stations, substations and other utilities, helping to protect and control key equipment. One of the most common type of inverters we get asked about are 110VDC to 230VAC rack mounted inverters – also known as a DC-AC converter*. These are often used as standalone inverters to work in conjunction with a 110VDC power system to back up AC power critical loads for: Workstations CCTV system Security system Critical instrumentation equipment (Specially for Power Stations) Server room equipment Control systems in renewables (solar installations) You have many options for this class of inverter, but they’re not all the same. Getting to grips with what features to look for in a modern inverter (especially if you’re replacing an older unit) can help you refine your search and (spoiler alert!) understand why the Helios ST TSI Bravo Inverter 5kVA 110VDC/230VAC should be at the top of that shortlist. * 110V or 125VDC Battery Chargers and Battery Banks are the most common voltage levels used in Switching and Zone substations. 8 Key Features to Consider in a New Inverter 1. What Inverter Capacity Do you Need? There is a wide range of industrial inverters available, and each is designed for a specific purpose. Choosing an inverter with the right capacity for your application can save you budget and physical space (lower capacity inverters tend to be more compact). Many applications like a workstation or CCTV system have low to medium power requirements, and a standalone 5kVA inverter is normally ideal. If you have larger needs, look at scalable solutions like the TSI Bravo DC/AC modular inverters 110VDC/230VAC. These provide modularity from 2.5 kVA up to 80 kVA. These have the capability to be sized and designed to handle inductive loads like actuators, motorized valves (instrumentation equipment in some power stations), air-conditioning, and so on. They can be indispensable in critical process control with pre-determined levels of redundancy that allow you to lose a controller or modules without losing output. 110V to 230VAC 2500VA Rack Mount Inverter 110V to 230VAC 5000VA Rack Mount Inverter 2. What Input Voltage Do you Require? Utility transmission, distribution and power stations commonly use 110VDC and 125VDC battery banks to backup equipment if the mains fail. So you’ll likely be looking for an inverter that covers this range. At the same time, you might want to consider that some communication applications like the microwave network or SCADA systems might only need 48VDC or 24VDC. Why does this matter? Because you may find it wise to choose an 110VDC/230VAC inverter from a product range that covers all your requirements. Within the Helios TSI Bravo ST range, while the most popular inverter is the ST110/230 and it has a wide input voltage range from 90-160VDC, you also have the option of the: ST24/230 covers 19-35VDC ST48/230 covers 40-60VDC ST220/230 covers 170-300VDC By choosing from the same product range, you’re building in flexibility, technical simplicity and efficiency around maintenance. 3. What Are The Power Sources? Many inverters can only handle DC power inputs. If your inverter uses TSI technology, it will be able to manage both AC and DC power inputs. With dual inputs, you can power critical loads off AC mains, switch to a DC power supply if the mains fail, and then switch back to AC later. That flexibility is why TSI technology is the gold standard for inverters. 4. What are the Physical Characteristics of the Inverter? The physical dimensions of an inverter will also help you to whittle down your shortlist. We recommend you look for a high-density, compact inverter that’s rack-mounted, modular and hot-swappable. Rack-mounted inverters take up less space and are easier to install and maintain. Being modular and hot-swappable makes repairs faster and cheaper if the inverter fails (see No. 6 What happens if an inverter fails). In our experience, DC to AC Converters (Inverters) are usually mounted within one of the communications racks or an independent AC Distribution Cabinet. 5. What is The Transfer Performance? This is the switching time between DC input and AC input. For example, high-quality inverters like the Helios ST TSI Bravo Inverter 5kVA 110VDC/230VAC have a zero-transfer time. So, if the AC mains goes out of the tolerance range or completely fails, the converter will switch seamlessly to the DC power system without any drop or delay. In the Bravo ST, this is called back-up mode and it all happens in 0ms. This zero-transfer time is critical for equipment that might misfunction if the input voltage is out of the tolerance range for even a split second. 6. Does It Have Remote Control Capabilities? Being able to monitor the health of your inverter is also essential. A modern inverter should provide an easy-to-use communication feature. For example, a T2S Remote monitoring interface that allows you to do online diagnostic and system integration through a Modbus TCP. 7. What Happens if The Inverter Fails? When an inverter fails, you’ll normally require a maintenance bypass to replace the faulty inverter – and that’s when you’ll want a solution that is modular, hot swappable and has an internal automatic bypass. The Bravo ST is designed this way. So if you have an N configuration with no redundancy, when one module fails, the Bravo ST will use its automatic bypass to switch to AC. You can then do a hot swap replacement without shutting down the AC input. For an N+1 configuration with two 2.5 kVA modules, the second module will continue to feed the load while you hot swap the first one. If the second module fails, the automatic bypass will kick in just like with an N configuration. 8. What Service Support Do Suppliers Provide? Even the best inverters can fail, so consider what service levels you expect to back it up before making any purchase decision. Does your supplier have the in-house expertise available? Will their technical experts provide after sales support? Do they operate a reliable supply chain for replacements? Can they

Helios introduces new programmable AC Power Sources

Helios has introduced three new programmable AC power source solutions, designed for research projects and testing critical applications. The new range complements Helios’ other power supplies for Automatic Testing Equipment (ATE), and is ideal for universities, laboratories, national research institutes, and critical manufactures. Reliable, flexible and easy-to-configure, the new systems can support research and testing across a wider range of science and technology critical applications, including: Country Safety ( Electrical testing for military environments) Health & Medical (Vaccine, Biomedical, Nutrition) Natural Environment (Atmosphere, Biosecurity, Oceans, Natural resources) Technology (Astronomy and space, Robotics, Cybersecurity, Renewable energy) Industrial Manufacturing New range promises efficiency, reliability and cost-effectiveness. The SP-300, SPS300 and SPTS range of AC power supplies are single phase and three phase power sources. They provide high power density, high reliability and high precision features in 2U/ 3U/ 4U/ 9U/ 17U/ 21U form factor from 600W up to 20kW. AC and DC mixed or independent output modes for voltage DC offset simulation Control via touchscreen or digital control interfaces Standard RS232 & RS485 and optional LAN & GPIB. Support both SCPI (Standard commands for Programmable Instruments) & MODBUS communication protocols Compliance testing to IEC 61000-4-11 / IEC 61000-4-14 / IEC 61000-4-28 / IEC 61000-4-13 Phase angle dimmer simulation Power line disturbance simulation High output crest factor which satisfies surge test requirements Output frequency 15-1000Hz, capable of setting output slope of voltage and frequency Combine units for multi-phase configurations Built-in power meter, which can measure 15 electrical parameters per phase, including voltage, current power, etc. Measure up to 40 orders of the voltage of current harmonics (SP 300 model) New Series of Single Phase & Three Phase AC Power Sources SP-300 1Ph Programmable AC Power Source 2.8A – 48A / 150VAC – 300VAC / 600W – 5kW Read more SPS-300 3Ph/1Ph Programmable AC Power Source 2.52A – 165.6A / 150VAC – 600VAC / 1.2W – 20kW Read more SPST 3Ph/3Ph Programmable AC Power Source 2.8A – 46A / 150VAC – 300VAC / 1.2kW – 15kW Read more Helios commitment to supporting science and technology The science and technology sector are vital to our country’s success. The sector plays a crucial role in improving our natural environment, economy, and quality of life. It also helps to protect people against natural disasters and climate change. That’s why Helios works closely with research institutes and technology centres. We understand the sector’s needs and provide fit-for-purpose products, supported with on-the-ground expertise and service, and a robust supply chain. We believe if we do our job well, the sector can reward Australia with new knowledge, discoveries, and patents. And this will increase the resilience and autonomy of Australia’s economy and safety. For technical support about our off the shelf products and customised power conversion solutions, get in touch today. Contact Our Engineering Team

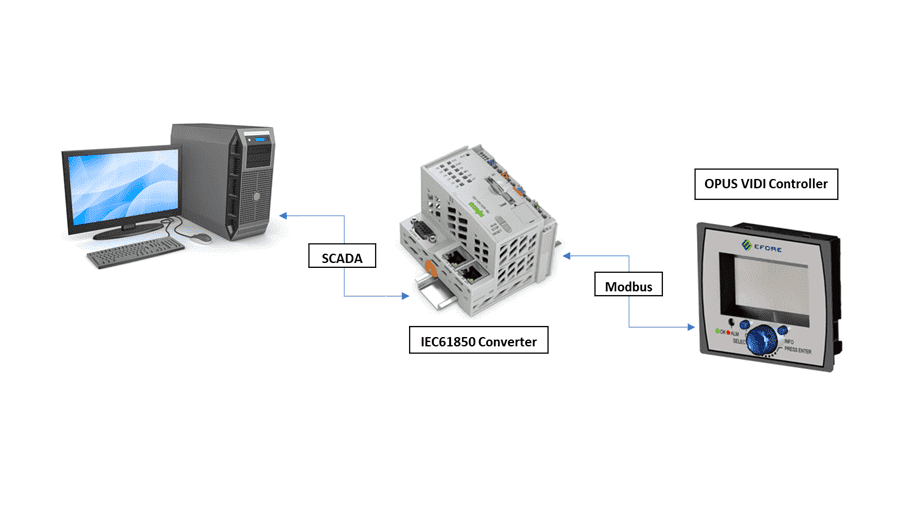

IEC 61850 Converter to monitor HE OPUS Battery Charger Systems via SCADA Network

IEC 61850 is a widely used standard for the design of substation automation systems and applications, or usually known as the international standard for communication in Substations. Substation engineers have become familiar with this standard overt the last years. The following links provide an excellent snapshot of it. Advantages of IEC 61850 Technical Overview and Benefits of the IEC 61850 Standard for Substation Automation IEC 61850 Converter to monitor OPUS Battery Charger Systems via SCADA Network Helios Power Solutions Group have been providing DC Power Systems over the last 35 years and Electrical Substations is one of the main critical applications where our DC UPS have been installed. Battery charging systems in substation provides security and reliability for critical DC loads such as SCADA System, protection, telecontrol systems, automation and signalling units, measurement and monitoring units and more critical equipment that represent the core of any distribution and transmission substations. We are thrilled to announce you that ENEDO Power Systems integrated by Helios Power Solutions Australia can now be communicated to SCADA systems via the IEC 61850 protocol. The IEC61850 standard enables integration and interoperability of equipment from different manufacturers which, in turn, can reduce the costs of wiring and engineering time, as well as improve system commissioning and maintenance tasks. Check Out Some Of Our Industrial DC Power Systems Solutions Using OPUS DC Power Components OPUS DC Power Solutions Dual 3.2kW Battery Charger System 110VDC with 40Ah Battery Banks Efore’s new IEC61850 converter has been developed in partnership with WAGO and provides IEC61850 SCADA compatibility via the WAGO controller which is connected to the OPUS system by Modbus. The IEC61850 converter can be installed inside Efore’s racks or cabinets providing full data measurement of system voltage, battery and load currents, alarms and other relevant parameters for battery backup systems. Additionally, an external IEC61850 converter can be connected to already installed OPUS systems and provide SCADA compatibility in existing installations. The addition of the new IEC 61850 converter into new and existing installations enables systems to communicate with other manufacturers’ devices that also support this standard, providing valuable interoperability critical to substation operations. Key functions include Energy Save mode, rectifier runtime counter, alarm configuration, real time clock with battery backup, inventory management and more. The VIDI+ controller can support up to 47 rectifier modules. Battery Health Diagnostics and Improved Battery Monitoring Features Added to VIDI Controllers Last but not least, based on customers feedback new features have been added to the VIDI Controllers including including Battery Lifetime Diagnostics, Battery Connection Quick Test and User Programmable Pre-warning and Critical Alarms. For technical support about our off the shelf products and customised power conversion solutions, please get in touch. GET TECHNICAL SUPPORT FROM OUR TEAM OF ENGINEERS IN AUSTRALIA Opus DC Power Systems & Accessories OPUS HE 7U Modular Battery Charger Up To 6kW Read more OPUS HE 12U Modular Battery Charger Up To 20kW Read more OPUS HE DC Power Systems MHE Rectifiers 2000W Read more OPUS HE OC0864 Wall Mount DC Power System 4.5kW – 12kW Read more OPUS HE WMC Convection Cooled Battery Charger 2kW Read more OPUS EDC Modular DC/DC Converter 500W to 10kW Read more OPUS DAC60000 Modular DC/AC Inverter 1-24kVA Read more OPUS MVPS Modular Industrial UPS System DC 4kW, AC 3.6kW Read more VIDI2 System Controller Read more OPUS HE DC Power Systems OC2066 24V – 220VDC Read more