- What is a leaky feeder, and how does it work

- What’s important about the DC power supply and battery backup

- Other Helios solutions for the mining sector

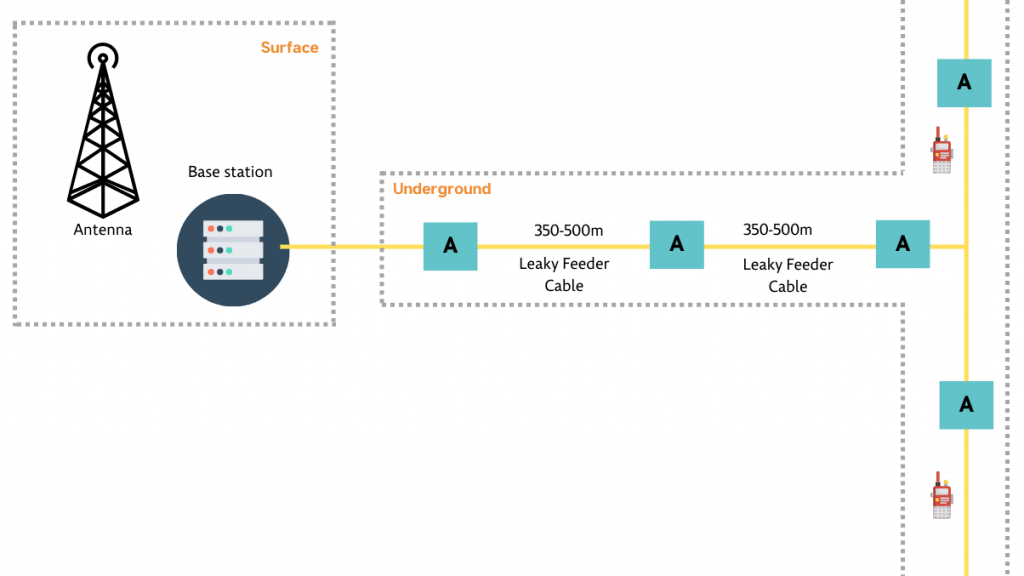

What is a leaky feeder

A Leaky feeder works by running a linear cable (radiating cable) through mines, tunnels or structures. These cables are then used as an antenna to connect devices for voice, video and high-speed data communications.

They’re a reliable, robust communication system that you can scale using amplifiers. These attributes make them ideal for mining, though you also find leaky feeders everywhere, from railway tunnels to commercial aircraft.

In a mine, a leaky feeder might look like this ⇒

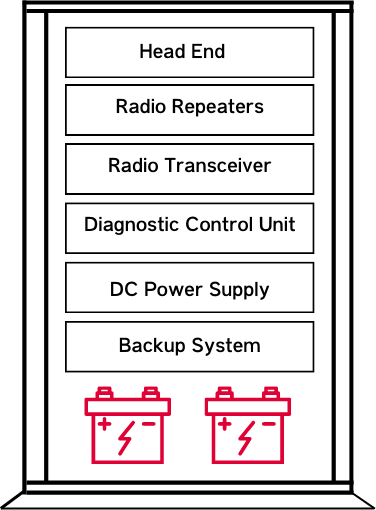

Central to the leaky feeder is the Head End Base Station.

This 19” rack mount cabinet not only connects the underground network and the surface antenna network. It also:

- Modulates and demodulates the VHF signals

- Splits and combines multiple channels

- Performs remote diagnostics

- Manages correct impedance matching

- Identifies faults

- Reports back to the network performance monitor

- Provides DC power supply to power the leaky feeder network

- Backs up power supply with a battery charger and battery bank

The last two points are potentially the most important. Why? Because no power, no leaky feeder, no comms. You could have an unsafe work environment without a reliable UPS solution for your leaky feeder.

Top 5 considerations for a leaky feeder DC power system

1. How robust is the DC power supply and backup?

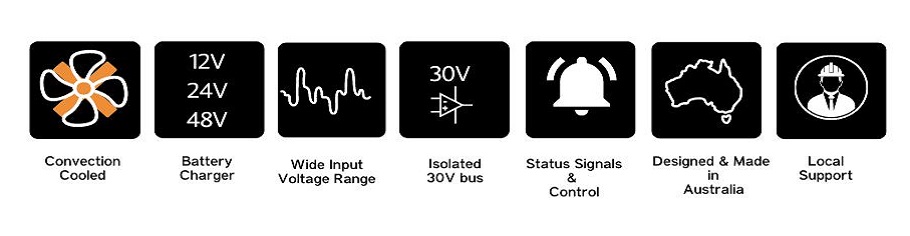

Your DC power system and backup need to operate flawlessly in a dusty, hot environment. Only shortlist solutions that are convection cooled (no fans) or have a high operating temperature.

2. Does it have a versatile design?

Look for solutions that are easy to install (i.e. rack mounted), have a wide input range for VAC (to withstand voltage fluctuations), and can have two different voltages levels ( 30V for the amplifiers and other for the charging batteries).

3. Can you monitor the system or control it remotely?

Realtime monitoring of the power supply should be a non-negotiable in any modern leaky feeder. So too should be remote monitoring via TCP/IP.

4. What customisations can you make?

You should be able to customise your DC power solution to your needs. Whether you want batteries charged at 12V, 24V or 48V, digital or analogue meters, lithium or lead-acid batteries – it should be your call.5. Is the power system locally produced and supported?

If something happens, how reliable is the supply chain for repairs? Are the components produced locally or on-hand? Are technicians available to support your teams?How does the Helios solution stack up?

At Helios work closely with leaky feeder producers, mining communication consultants and mining operations in Australia. So we understand what works best in mines here and how to make the customisations you might need.The Helios Power Systems leaky feeder power supply is a battery-backed, convection-cooled (no fans) DC power system that can be fully monitored and is designed for harsh underground mining applications.

This system has the DC power supply for charging the backup system (batteries) and the 30VDC required for powering up the leaky feeder network (power amplifiers) in the same 2U rack unit. In case of mains failure the battery bank can provide power for ### hours.

Standard Features

- Convection cooled ideal for dusty environments ( this depends on the output power required)

- Wide input range 180-300VAC (capable of handling transient spikes)

- 12V, 24V or 48VDC options for battery backup

- 30VDC to power amplifiers

- Short circuit and OVP protection

- High operation temperature

- Battery Circuit breakers

- Easy installation, diagnosis and management

- Active relays to turn loads ON/OFF

- Designed and made in Australia

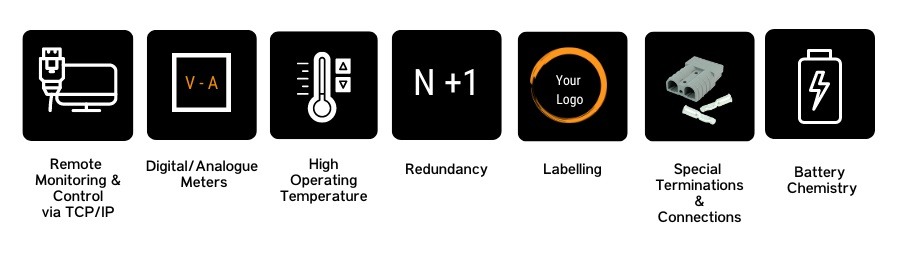

Optional Features

- Digital or analogue meters for Voltage and Current

- Remote control and reporting over TCP/IP. Ability to report back to the control room in real-time

- LED Indications alarms – front panel

- Terminals – Phoenix or Stud

- N+1 Redundancy

- Specific alarms

- System reset button

- Battery Backup type (lithium and lead-acid) and autonomy

- Conformal coating

Some of the Leaky Feeder DC Power Systems manufactured by Helios Power Solutions

Other Helios solutions for mining applications

Helios also support the mining sector with a range of other custom solutions for operational safety and continuity. These include:- Battery chargers and battery banks for substations and switchgears

- Power supplies and DC distribution panels for SCADA & telemetry networks

- Fully customised power distribution panels via TCP/IP

- Power systems for security surveillance and emergency systems

For technical support about our off the shelf products and customised power conversion solutions, get in touch today.